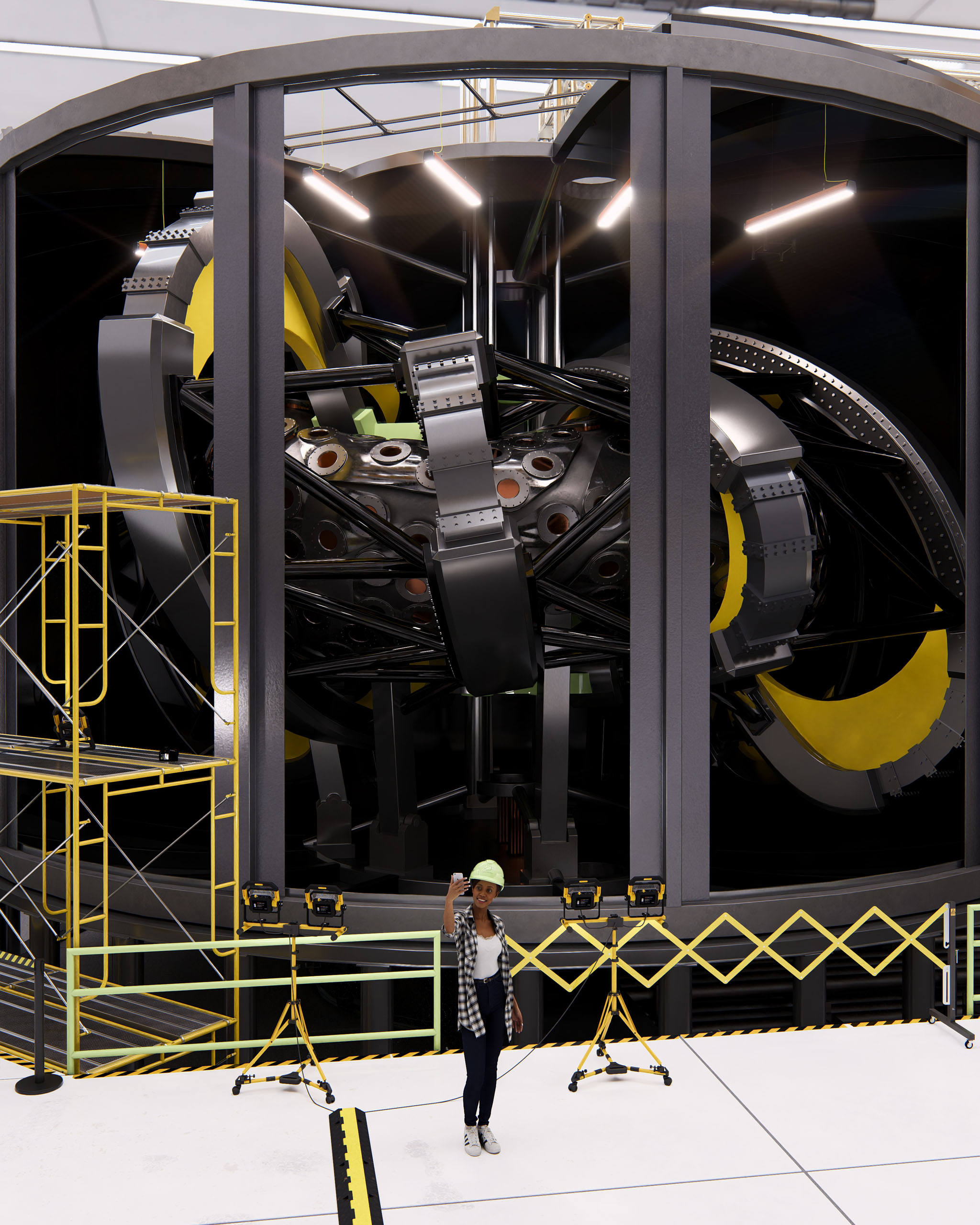

Thea Energy’s Eos integrated stellarator facility will create power plant relevant, steady-state fusion using the Company’s simplified architecture. Eos is a critical step towards an abundant source of zero-emission energy, and Thea Energy’s first commercial fusion power plant, Helios.

Thea Energy was founded to create a faster and simpler approach to commercializing fusion energy. Eos leverages arrays of mass-manufacturable planar (flat) magnet hardware and revolutionary software-based control systems.

We have optimized Eos to relax engineering and manufacturing requirements, with simpler hardware and 450+ independent variables to continually re-optimize performance across a lifetime of real-world system operation. Our architecture has orders of magnitude more tolerance to hardware, manufacturing error, construction variability, and system wear and tear than 3D modular coil stellarators.

Our team has been continuously improving stellarator physics and engineering using the latest advances in high-speed computation and AI.

Over the past year, recent breakthroughs have allowed us to utilize roughly 50% the number of coils compared to the originally proposed system design. Eos is now further optimized to only require one size shaping coil. This enables the mass manufacture of magnet hardware via simple, cost-effective means (think automotive assembly lines). This reduction in coils and number of unique parts also creates modularity across system components and subsequently more efficient maintenance. Additional space allows for entire system sections to be more easily assembled or removed for maintenance, and for various components such as ports, plumbing, wiring, and heating subsystems.

Eos uses a set of planar encircling coils and planar shaping coils that work together additively to precisely and efficiently create stellarator magnetic fields. This planar coil stellarator architecture can create one of the best (i.e. most accurate and efficient) coil-to-plasma field reconstructions. Our dynamically controlled planar coils can produce magnetic fields with more than 10x better optimization than existing stellarator systems such as W7-X (Bonofiglo 2025 and Landreman and Paul 2022).

Detailed peer-reviewed findings on Thea Energy’s breakthroughs including Eos and the system’s core magnet technologies can be found under Presentations & Publications.

Subscribe to get the latest updates, insights, and more delivered straight to your inbox.