Development Milestones

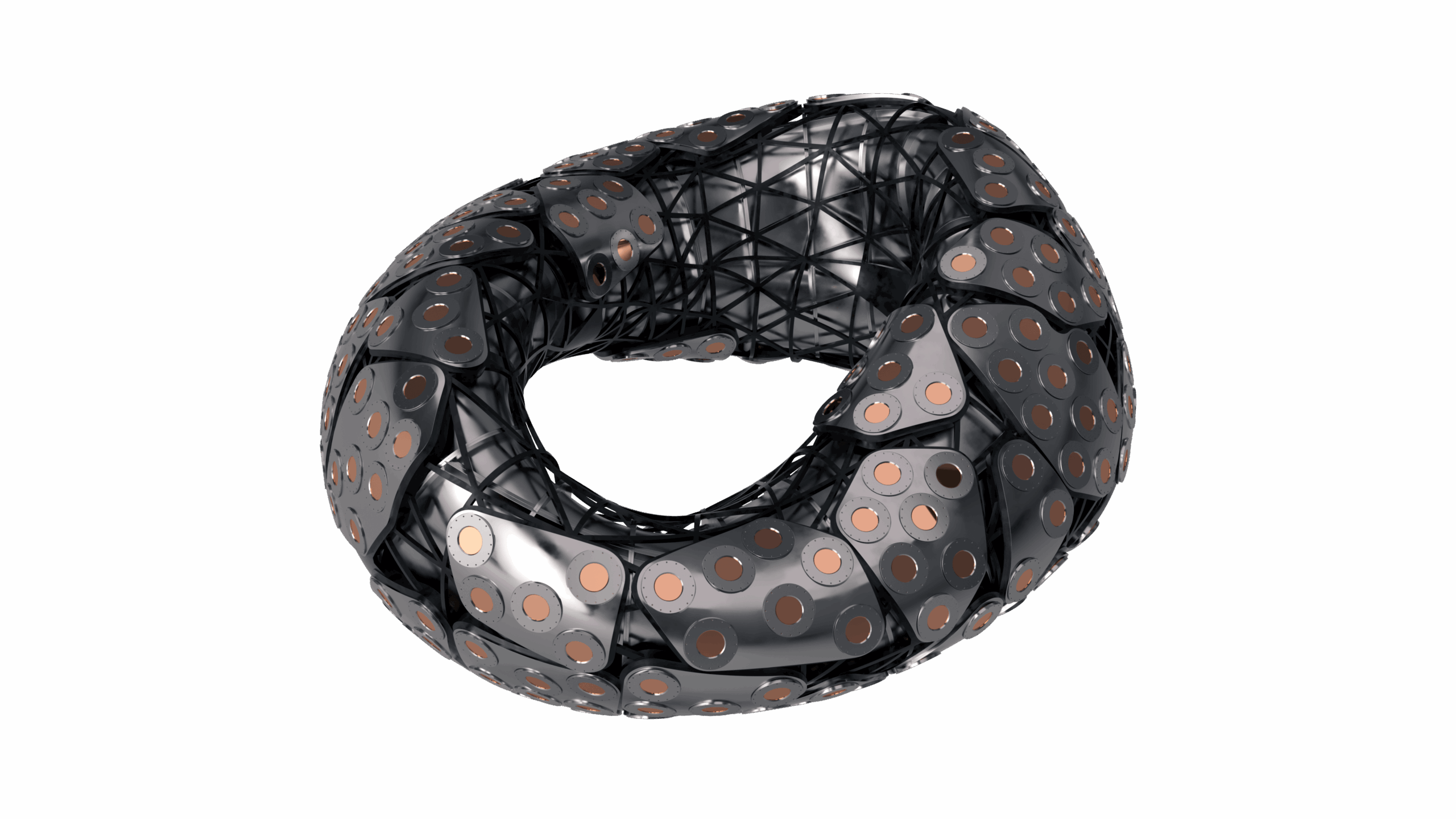

We’ve shown that the stellarator can be built in a simpler and scalable way

Learn why the planar coil stellarator architecture gives us a more practical and efficient path to commercialize fusion energy.

Subscribe to get the latest updates, insights, and more delivered straight to your inbox.

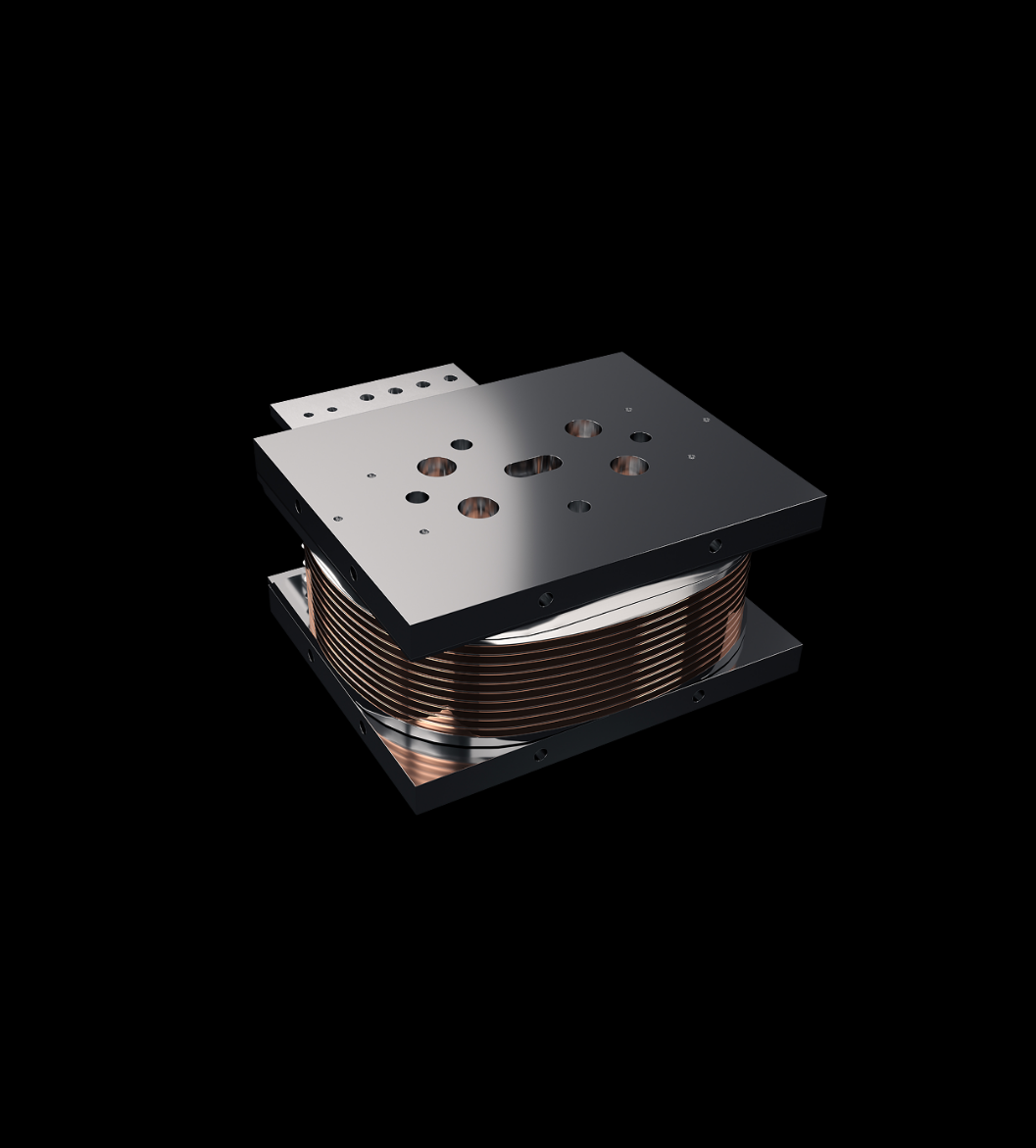

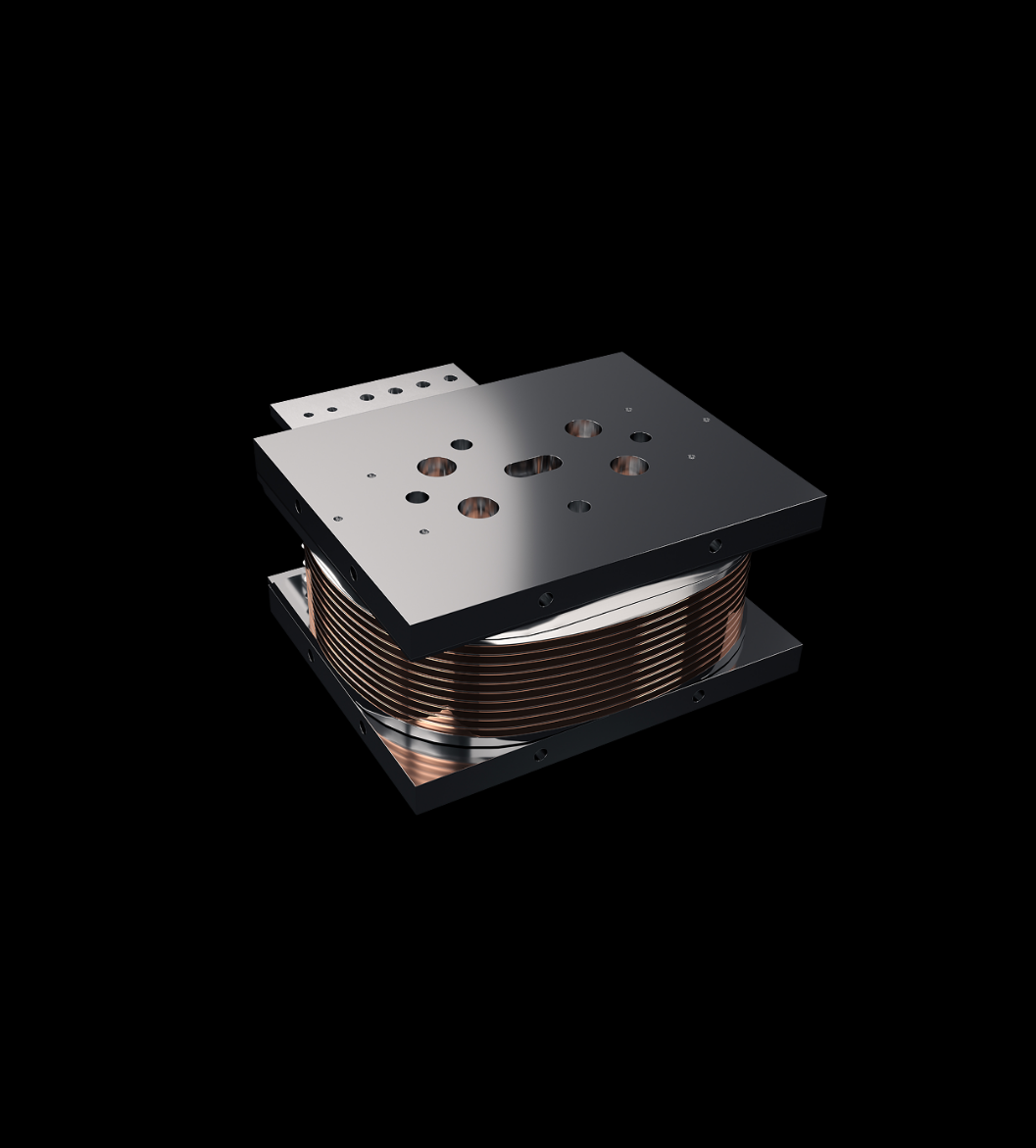

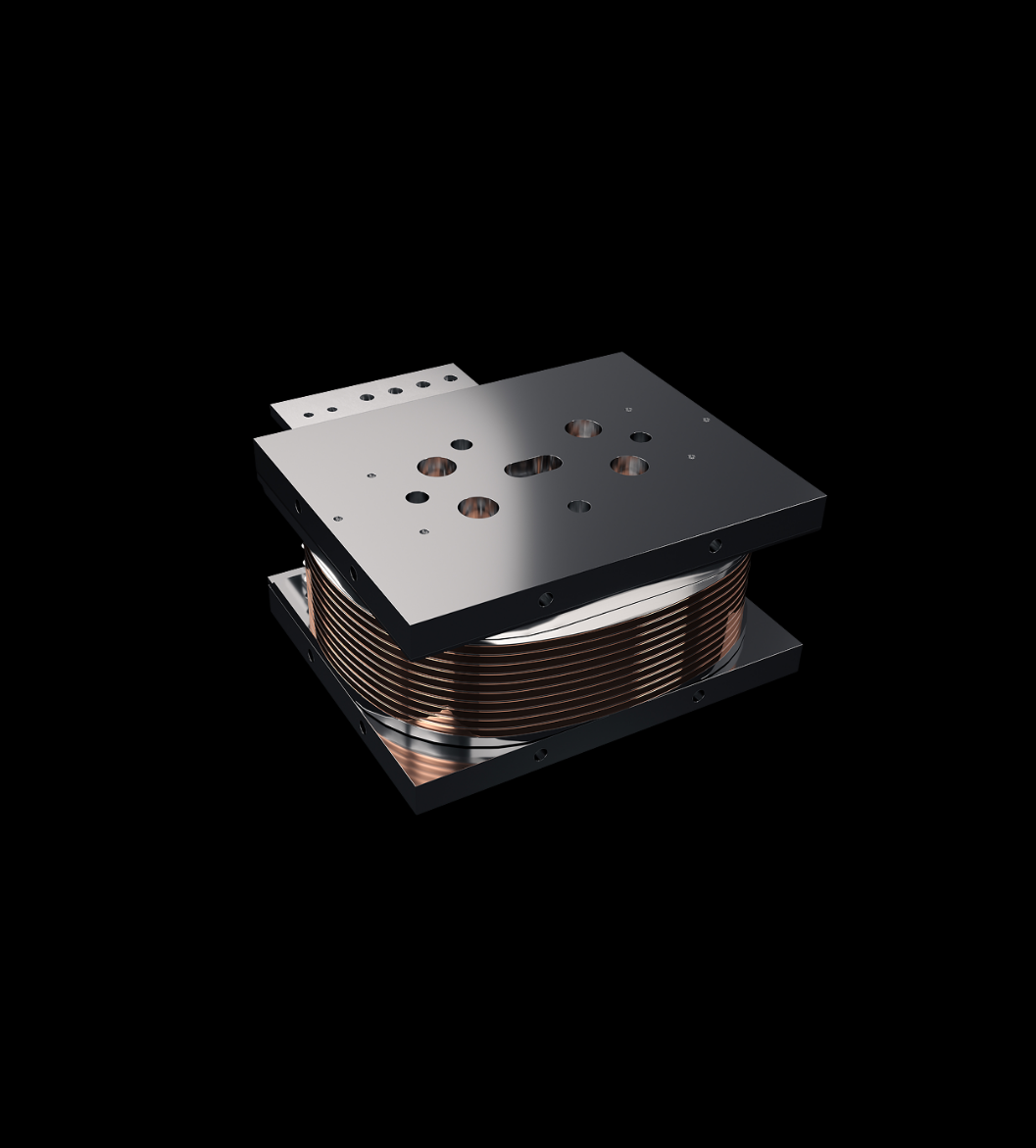

Following the close of our Series A, we rapidly began prototyping HTS magnets.

Our proprietary architecture and IP allow for all magnet systems to be constructed using more conventional manufacturing methods, a radical simplification of stellarator magnet design and a critical advancement allowing for the deployment of stellarator fusion power at scale.

We’re able to iterate our core fusion tech at a quicker pace.

By utilizing an array of smaller and simpler planar magnets, we have been able to advance our tech from generation to generation on a time scale of months, not years (like prior modular stellarator magnets) and for orders of magnitude less capital.

We demonstrated the performance and controllability of small and simple magnets for fusion energy with our latest planar coil 3×3 magnet array system. The world’s first superconducting planar coil magnet array created and controlled stellarator-relevant magnetic field structures. These results are the hardware validation to the leading approach for a maintainable and dynamically controllable stellarator fusion system.

Further testing supports analytical models showing recovery and reliability of systems leveraging the planar coil stellarator architecture, where systems can continue to operate if a coil fails. Additional work has also shown the resiliency of this architecture and its ability to actively control and tune out hardware errors via Thea Energy’s dynamic software control system. Next, the Company is scaling to manufacture its final Eos-spec shaping coil magnet, Amphion.